In the 1980s, Mr. Moli Seng, Chairman and Founder of KLD, started first promoting foreign industrial products in mainland China. In 1998, KLD-industrial Developing Co., Ltd. was established in Macau to distribute CLAYTON steam generator...

In the 1980s, Mr. Moli Seng, Chairman and Founder of KLD, started first promoting foreign industrial products in mainland China. In 1998, KLD-industrial Developing Co., Ltd. was established in Macau to distribute CLAYTON steam generator. With years of effort and hard work in a market with only firetube boilers, the Chinese market final start to recognize the advantages of Clayton Once-through coil type steam generator technology. Particularity on Safety, Efficiency and the Compact Design. KLD has gradually expanded its business in China with offices expansions. With trust and faith and 20 years of cooperation, Mr. Seng set up a factory in Hangzhou in 2003 -Hangzhou KLD Boiler Equipment Co., Ltd., mainly engaged in the assembly business of CLAYTON products in China to help customers reduce costs.

With the great success of the assembly business in China, KLD gradually developed from the assembly business to configure its own complete steam generator production line in a few years. In 2006, the company moved to Hangzhou Economic and Technological Development Zone, invested and built a new factory by KLD-industrial Developing Co., Ltd. -KLD Thermal Equipment Corporation (hereinafter referred to as "KLD thermal "). Working with Clayton industries who has nearly 90 years of production history in the United States, KLD set up a joint venture with Mr. John Clayton the CEO of Clayton Industries to manage the sales and technology in China.

The KLD Thermal factory covers an area of about 30 mu, flooring 11,430 ㎡. The factory is equipped with patented equipment such as coil winders which design specifically for Clayton-KLD products, as well as all the tooling equipment, all of them specially design and manufactured by KLD. The current annual output of standard products is 200 sets at around 300 million RMB. The annual output of non-standard products such as marine boilers, high-pressure, super-critical and other high parameter products, etc. can achieve to 100 sets with value of 800 million RMB. The KLD Thermal factory carries Chinese TSG “A” level boiler manufacturing license, “ASME” license, CE/PED license, CCS license, and most marine licenses. Other safety and international certificate such as ISO, SEDEX 4Ps, WAC, KLD is recognized as "national high-tech enterprise" and with an excellent reputation of a company with highest integrity in the industry.

Innovation is the cornerstone of KLD. With Clayton's technology as foundation, KLD thermal has made bold exploration, broken throughs on designed & manufactured steam generators :

Single unit of 30-50 t/h steam generator, Superheated Steam Temperature ≥ 600 ℃ , Supercritical pressure unit above 4800 psi / 33 MPa, complete mobile containerized heating system, hot water generator, F series Steam generator system, etc. All aim to provide our clients with best steam and heating technology on the market, with only one goal – creating value for our clients and help them achieve their corporate goal.

It is with pleasure that we announce, KLD has recently procured 55 mu of land the Hi-Tech Industrial Park in the City of HaiNing 10 mins away from our current plant. We are going to build a new industrial complex with planned production starting in 2023, as the current factory cannot meet the increasing demand in the market.

Committed to providing the society with safe, efficient, and innovative revolutionary industrial steam equipment.

Committed to improving employee happiness, providing a development platform for growth and achievement of self-worth.

With years of effort and persistence, KLD Thermal is premier brand of China's industrial boiler market with our unique products.

The unique and exquisite technology, process, quality, safety, low energy consumption, high efficiency and client focused after service system have contributed a lot to KLD Thermal energy Company's position in the competitive boiler industry in a short period of time. KLD has always taken the requirements of users as the highest standard for R&D, design and manufacturing, and really put the words into implementation. Instead of pursuing the false data issued by the so-called laboratories such as thermal efficiency of 100% and 104%, KLD focus on improving thermal efficiency during actual operation and allow our customers get real benefits – money, labor and time saving from using KLD Steam Generators.

KLD has adopted series of policies to encourage our engineers in the development of products that fits customer requirement. Our employees' pursuit of perfection by asking critical questions and brainstorming suggestions are to be rewarded, all of which allowing use to always stay on top of our competitions.

It is KLD's lifelong mission to be the best in the steam business, to be above and beyond, to innovate and shine where others couldn't.

Company – it is the concept where a group of like-minded individuals come together trying to achieve a common goal. A company could shine and grow successfully only when everyone in it is willing to give a certain, it is the foundation where a company could truly be socially responsible. At the same time, giving back the employees with a sustainable development, promising, professional working environment.

Where our clients enjoy product and service from a mature, socially responsible company with upmost integrity. KLD will abide by its commitment to the society and will continue to develop new technologies for our every moving environment. KLD will make great efforts for China's commitment to reduce carbon emissions in the world.

KLD has always adhered to our moto of "k-knowledge, L -legacy, D-dedication". In the fierce competition, a large number of companies make fraud and plagiarism for the sake of profit. KLD has always insisted on self and integrity management, making it unique in the market and gaining the trust of users.

Clayton is a well-known global steam generator brand. In the late 1920s, American businessman William Clayton invented a device – STEAM GENERATOR that can quickly produce steam.

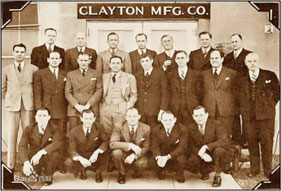

In 1930, Clayton Manufacturing Company (later Clayton Industries) was formally established in the United States. Its products are mainly for the U.S. military, supporting U.S. Navy aircraft carriers, cruisers and other ships. After the end of World War II, parts of technologies and products were transferred to civilian use and sold to large industrial enterprises in Europe and America.

In the early 1940s, Americans put forward the concept of mobile, integrated skid mounted. The invention and manufacture of integrated skid mounted movable steam generator system can be quickly installed and used, which is widely used in military, oil thermal recovery industry and heating in remote areas. The main advantage of this product is that it is flexible and does not need civil engineering.

In the 1980s, Mr. Moli Seng introduced the brand of Clayton and its technology to China and founded KLD to develop energy-saving and environment-friendly boilers in China.

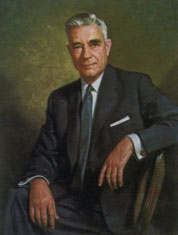

Founder of Clayton industries

Team of Clayton industries in early stage in 1935